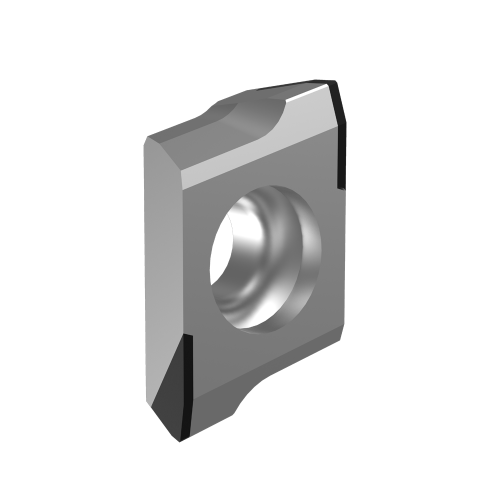

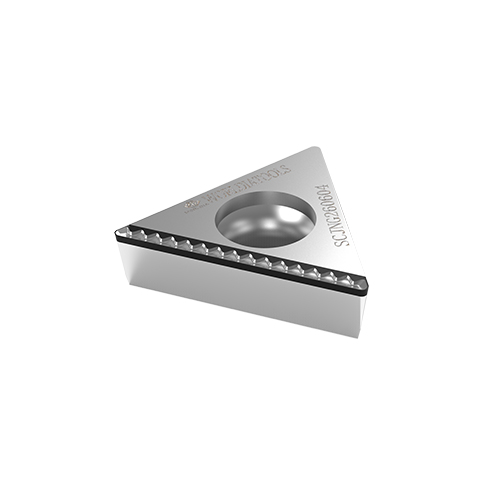

Tools and Inserts for turning

With the new BlackstarTM CTCK110 grade and the proven BlackstarTM CTCK120 , all applications of cast iron machining can be covered. The two grades, with three negative and one positive geometry, offer a consistent programme for all applications.

Tools and inserts for milling

The new MaxiMill 491 shoulder milling system from Cutting Solutions by CERATIZIT features 8 usable cutting edges per insert and shows excellent performance, quality and price-performance ratio.

Solid carbide tools

Process security & precision to depth Trust the deep hole drilling specialist in the market. As deep holes depend very much on the previously produced pilot hole, Cutting Solutions by CERATIZIT has optimised the drilling process with special geometries.

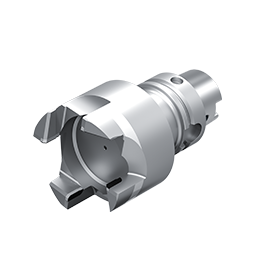

Spindle nose tools

To achieve the best possible performance with our cutting tools, Cutting Solutions by CERATIZIT now offers a start programme for spindle nose tooling. Benefit from an even better.

Best Products

More About Us

Using the online solution CONFIGURATE, it is possible to configure a customised semi-standard tool with only a few mouse clicks. Thanks to the new CONFIGURATE tool we are able to offer simple and easy order processing of customised solid carbide tools. You can configure a customised semi-standard tool with just a few mouse clicks in our E-TECHSTORE â 24 hours a day, 7 days a week.

- Offers and orders of individual tools - as fast and easy as for any standard tool.

- Availability 24 hours a day. Order regardless of business hours, thanks to fully automated processing.

- Easy to use thanks to menu-guided navigation: obtain your individual tool in just a few steps.

- Optimised for tablet PCs and smartphones.

Thanks to the user-friendly design and intelligent navigation you will quickly and easily find the product information you need. We have simplified the ordering process. Recurring orders are now also possible. Furthermore we have optimised our shop for use with tablet PCs and smartphones. In the new profile area you can manage your personal data.

Why Choose Us

Widia Video

Partners We Work With

We also continue to expand our reach through our distribution and channel / brand strategy touching more customers through our strong distribution partnerships. Kennametal delivers productivity and savings to our customers across a range of industries and networks. Brand portfolio management drives down our cost-to-serve as we continue to grow and makes our brands more distinct for our customers.